Gooda Wj

The machining center is not equal to the CNC milling machine. The biggest difference between the machining center and th

Description

Basic Info.

| Model NO. | WJ-1512NC |

| Milling Cutter Structure | Indexable Type |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Spindle Sleeve Diameter | 220mm |

| X/Y/Z/W Travel | 1500*1200*650mm |

| Distance From Spindle Center to Workbenc | 100-1300mm |

| Spindle Maximum Speed | 3000r/Min |

| Spindle Taper | Bt50 |

| Transport Package | Wooden/Steel Box |

| Specification | 6700*4200mm |

| Trademark | GooDa |

| Origin | China |

| HS Code | 84596190 |

| Production Capacity | 600sets/Year |

Product Description

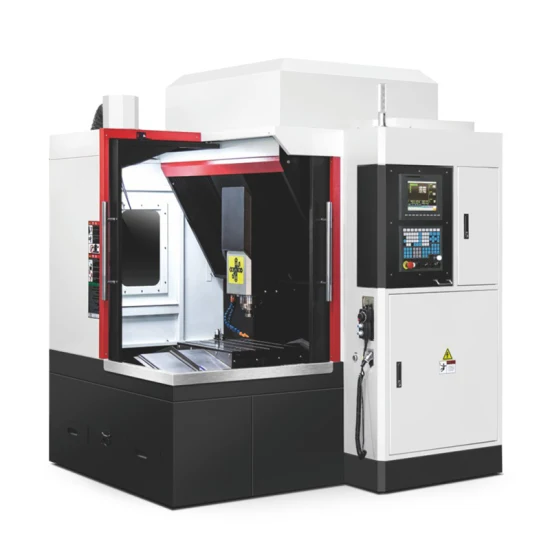

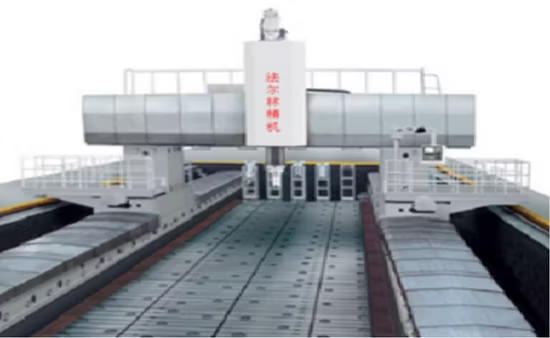

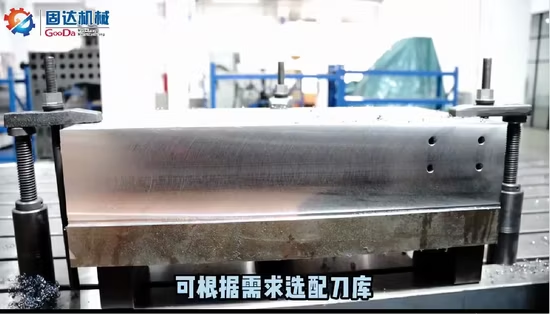

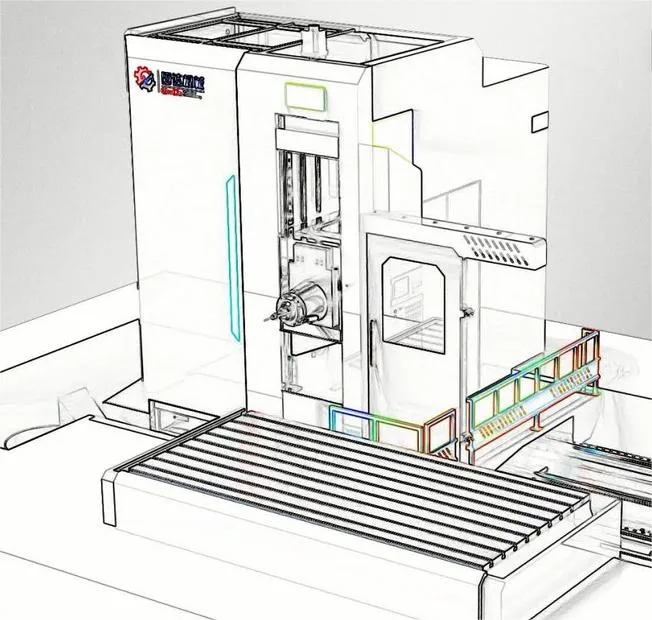

The machining center is not equal to the CNC milling machine. The biggest difference between the machining center and the CNC milling machine is that the machining center has the function of automatic tool exchange. After the workpiece is clamped once on the machining center, the machining tool on the spindle can be changed through the automatic tool changer, and various processes can be processed on more than two surfaces, such as drilling, boring, reaming, tapping, grooving, etc. Various processing functions. And there are multiple tool changing or tool selection functions, so that the production efficiency is greatly improved.GooDa frame opening machine WJ-1512NC, processing stroke 1500*1200*650mm (L*W*H), high rigidity, strong stability, optional control system, stable operation, high control precision,Low failure rate The machine tool has the functions of milling, boring pin, drilling pin, tapping, etc.; it can meet the processing requirements of various materials and is suitable for heavy cutting

Horizontal machining center Specifications(rough frame machine)

| Items | Unit | WJ-1512NC |

| X/Y/Z/W Travel | mm | 1500*1200*650 |

| Table size | mm | 1500*1100 |

| Max loading weight | ton | 10 |

| Distance from spindle center to workbench | mm | 100-1300 |

| Diameter of the spindle sleeve | mm | 220 |

| Spindle taper hole/pull nail | BT50-45° | |

| Maximum spindle speed (1:2 deceleration of synchronous belt) | r/min | 3000 |

| (X/Y/Z) fast shift | m/min | XYZ:8 |

| Ball screw (upper silver) | mm | XYZ:Φ63*10 |

| Guide rail form (roller precision grade) | mm | XYZ:roller55 |

| Spindle motor recommendation(IMK) | kw | Standard 30kw |

| XYZServo motor recommendation | Nm | XYZ:22Nm |

| Space | mm | 6700*4200 |

| Machine weight | ton | 20 |

Bed + base:The inverted "T" bed structure ensures that the machine tool has sufficient rigidity and stability during operation; the whole machine uses ANSYS for static structural force analysis and vibration frequency analysis to ensure the rigidity of the machine tool, reduce machine tool vibration, and improve tool quality. service life.Column:Y-axis overall double-wall moving column structure, high-quality HT-300 casting after secondary annealing treatment, to ensure long-term shock resistance without deformation, excellent stability of machine tool precision, and long service life.

Head:Four 55# extended heavy-duty roller guide rails ensure shock resistance for heavy cutting; the headstock is equipped with a nitrogen balance system to reduce wear and load on the vertical screw; improve the dynamic response speed of the machine tool and the service life of the machine tool.Spindle:The diameter of the spindle sleeve is increased to enhance the cutting rigidity of the spindle, and the maximum speed can reach 3000rpm; the spindle is equipped with a large flow cooling system, which can effectively control the temperature rise of the spindle and ensure the long-term efficient and stable operation of the spindle.Z-axis movement:Z-axis movement is the overall movement of the column. The rigidity of the Z-axis and the spindle head is always consistent throughout the entire stroke of the Z-axis, reducing the vibration of the tool when machining deep cavities. For the telescopic Z-axis of the ram, the rigidity of the spindle head decreases with the increase of the Z-axis stroke.

Dongguan Gooda Machinery Manufacturing Co., Ltd.,established in 2012, is a domestic set of CNC milling machine research and development manufacturing,sale and service in one of the national high-teach enterprise. At present, the company is the largest manufacturer of CNC bilateral milling machines in the world.The company's main products: CNC double face milling machine, CNC high-speed sawing machine, CNC vertical milling machine, CNC planer milling machine, CNC gantry milling machine, CNC machining center, CNC gantry machining center, multi-axis deep hole drilling machine, CNC three-axis chamfering machine, CNC surface grinder, turning Trigger.

GooDa Machinery Enterprise Culture:Corporate mission: provide customers with high -precision, high -quality CNC double -headed double -headed machine, and provide customers with customized innovative technologies on demand;Corporate ingenuity: Adhering to the ingenuity of his own ingenuity for more than 10 years, he strives to become a high -quality enterprise for CNC machine tools;Corporate purpose: adhere to customer first, integrity management, provide customers with guaranteed high -quality after -sales service; adhere to creating more well -being for employees;Quality and quality: Adhering to scientific and technological innovation, winning the market with better quality and quality, and insisting on excellence in product quality;Enterprise Vision: Deliven to promote the development of large, heavy metal profile processing industries, and work unremittingly to create independent research and development and innovation national brands.

Our Contact

Send now