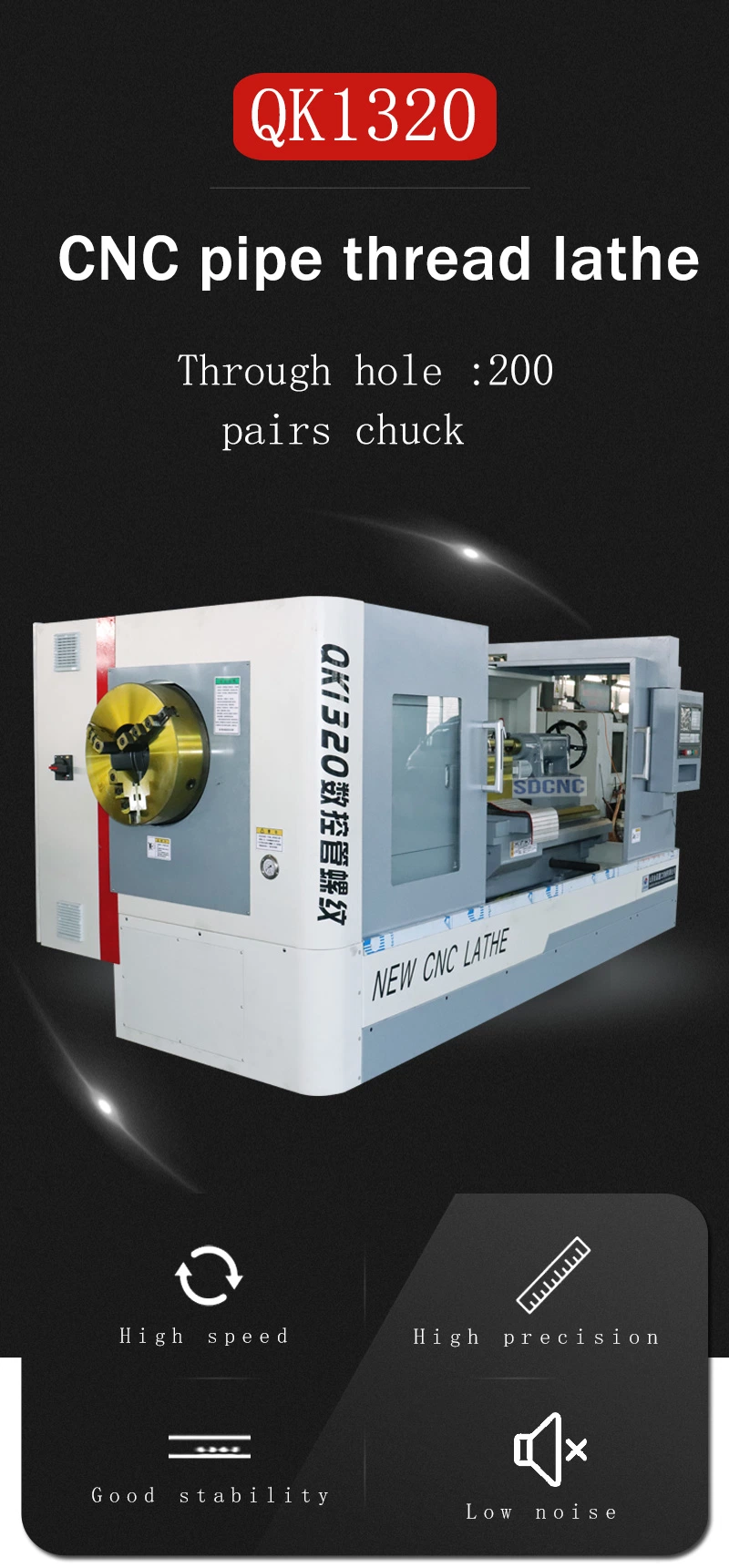

CNC Pipe Thread Cutting Machine Qk1319/Qk1320 /Qk1322CNC Oil Pipe Lathe

Description

Basic Info.

| Model NO. | QK1320 |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | Economical CNC Machine Tools |

| Certification | CE |

| Condition | New |

| Transport Package | Customer Request |

| Specification | 1850*1850*3300 |

| Trademark | SDCNC |

| Origin | Shandong China |

Product Description

Product Description SDCNCThis series CNC Pipe threading lathe is mainly designed for processing internal and external pipe threads including metric, inch, module, DP and taper threads, as well as having all the common functions of normal CNC lathe such as processing the inner bore and end face of shafts and disks. This series lathe machine is widely used in industries including petroleum exploiting, minerals mining, chemical piping and geological prospecting, it is high-efficiency equipment in processing and repairing drilling pipe, drilling rod, thread coupling and so on.

Characteristic

1.Big spindle bore and double chuck to ensure process big diameter pipe.

2.One-piece bed adopts high strength iron to ensure rigidity and precision.3.Ultrasonic frequency quenched guide-ways ensure good wear-resistance.4.Carriage and guide way contact surface use Turcite B to maintain accuracy.

1. Siemens controller

2. NC turret

3. Automatic Lubrication

4. Coolant Pump

5. Semi-shield1.

1. Fanuc or other brand CNC controller

2. Quick change tool post3. Hydraulic turret or Power turret4. Pneumatic chuck5. Hydraulic tailstock6. Pneumatic position limiter7. Tool setting arm8. Full-shield1.

| Item | Unit | QK1320 | ||

| Manual | HYD | |||

| Capacity | Swing over bed | mm | 630/800 | |

| Swing over cross slide | mm | 340/520 | ||

| Distance between centers | mm | 1000-6000 | ||

| Guideway width | mm | 50-220 | ||

| Max. load capacity | mm | 550 | ||

| Spindle bore | T | 3 | ||

| Spindle | Spindle bore taper | mm | 200 | |

| Spindle nose type | - | VF.4 steps | HYD 4 steps | |

| Spindle speed range | rpm | 20-600 | ||

| Chuck | mm | Φ500 4-jaw manual | ||

| Turret | Turret/tool post | - | NC turret 4 position | |

| Tool shank size | mm | 32×32 | ||

| Feed | X axis travel | mm | 320/420 | |

| Z axis travel | mm | 1000-6000 | ||

| X axis rapid traverse | mm/min | 4000 | ||

| Z axis rapid traverse | mm/min | 6000 | ||

| Tailstock | Tailstock quill diameter | mm | Φ100 | |

| Tailstock quill taper | - | MT5/MT6 | ||

| Tailstock quill travel | mm | 250 | ||

| Motor | Main spindle motor | kW | 11 | |

| Coolant pump motor | kW | 0.25 | ||

| Dimension | Width×Height | mm | 1880×1850 | |

| Length | mm | 3300-8300 | ||

| Weight | Net weight | T | 4.5 | |

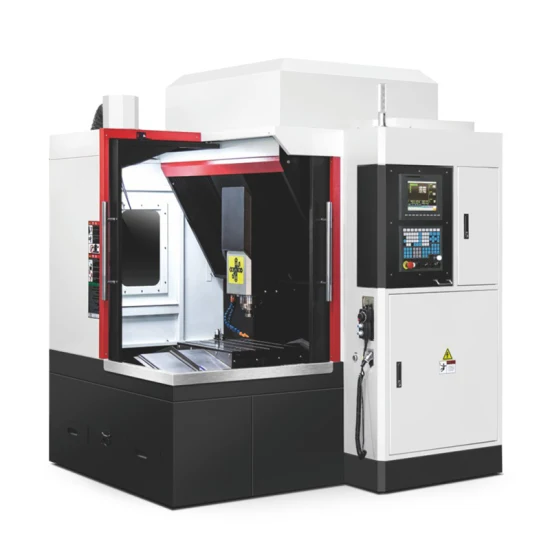

Prev: WMTCNC 4 Axis 5 Axis Vertical Milling Machine VMC600L CNC Machining Center Price

Next: Heavy Duty Large Hole Horizontal Metal QK1363 CNC Pipe Thread Lathe Machine

Our Contact