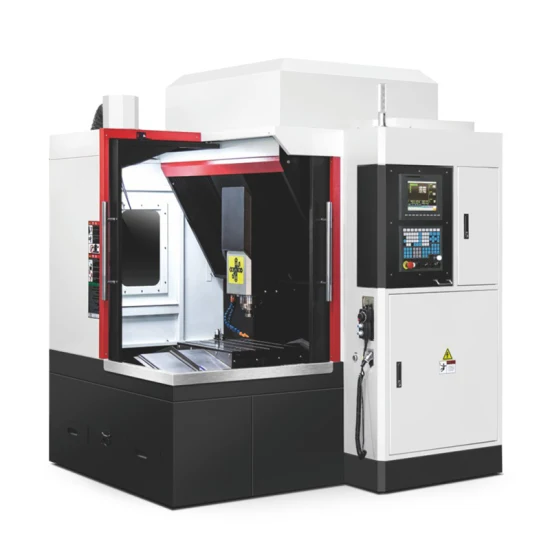

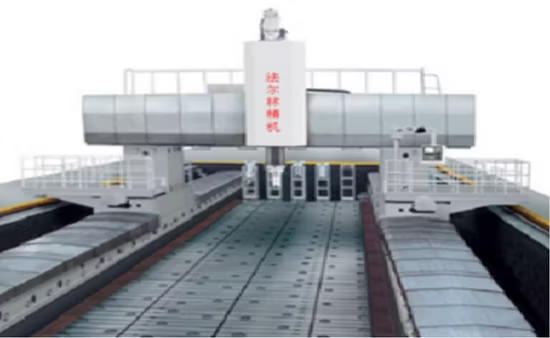

CNC Double Column Milling Machine Gantry Machining Center

Description

Basic Info.

| Model NO. | YSM-7038 |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Max Workpiece Length | 6400mm |

| Max Workpieces Width | 3000mm |

| Processing | Drilling, Tapping, Milling, Surface Milling |

| Max Workpieces Weight | 42t |

| Transport Package | Seaworthy Package |

| Specification | 7000*3800*800mm |

| Trademark | Yangsen |

| Origin | China |

| HS Code | 8457103000 |

| Production Capacity | 1000 Sets |

Product Description

Double Column Machining Center Structure Characteristics

CNC Double Columns Milling is mainly heavy milling top and bottom surfaces of the custom plate which is a specially designed vertical milling machine. The integrated high rigidity T-shaped bed, double-column structure, and crosswise overhangs structure ensure high straightness accuracy and excellent workability.

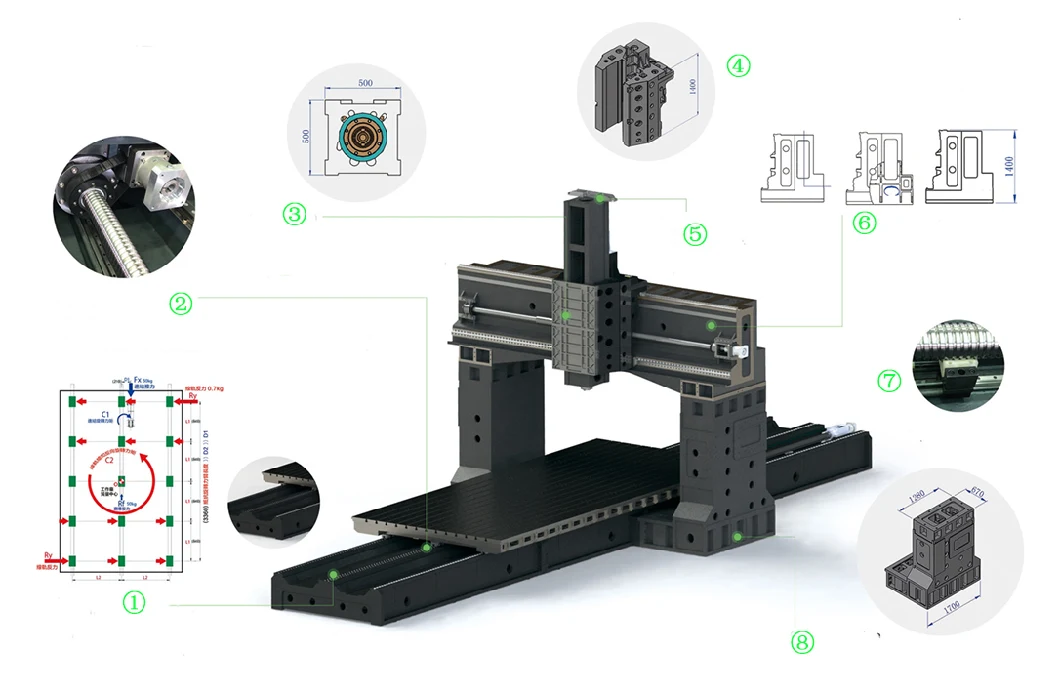

1.Base structure

Compared with the double-guideway design, the rigidity is 50% higher; Compared with the four-guide ways design, it is more symmetrical and evenly distributed, reducing the power loss caused by the resistance of the multi-guideway slider;3m wide worktable, 2.1m base linear guideway. It is the best ratio span of 0.7.

2. Gantry moving nut structure

The X-axis is driven by a moving nut, and three-point support is used in the middle to maintain the rotation accuracy of the ball screw rod. At the same time, the load capacity is large, and the cutting vibration resistance is good. It can improve the dynamic characteristics of the machine tool and increase the accuracy, stability, and service life of the machine tool.

3. Square ram

Bigger dimensions 500*500, the original size is 460*460. It is a more heavy-duty design; The built-in direct connection design reduces the power transmission consumption from the spindle motor to the spindle.

4. Slide features

The large-size and heavy-duty design ensure that the upper part of the ram is firmly hugged by the three elongated sliders, and the lower part is supported by the four standard sliders.

5. Nitrogen counterweight

Reduce the load of the motor and the bearing force of the ballscrew, increase the life of the ballscrew and the motor, and the acceleration of the Z axis to ensure processing accuracy.

6. Beam structure

The stepped L-shaped design improves rigidity; The concave C-shaped structure has better-bending resistance;

Large section design; Finite element analysis.

7. Ballscrew support frame system

8. Column structure

The 1.28m ultra-wide design of the column reduces the overall cutting vibration and makes the machine tool stable.

Double-Column Machining Center Parameters

Model | YSM-7038 | ||

Subject | Specifications | Units | |

Travel | X-Axis | mm | 7000 |

Y-Axis | mm | 3800 | |

Z-Axis | mm | 1250(Optopmal 1500) | |

Spindle Nose to Worktable | mm | 350-1600 | |

Three-Axis Guideway | X/Y Heavy Load Roller Linear Guideway Z-Axis T-Type Ram Box Way | ||

Door Width | 3800 | ||

Type of Ram | Square-Type Ram (500x500) | ||

Worktable | Worktable Size(L*W) | mm | 6400*3000 |

Maximum Table Load | t | 42 | |

T-Slot | mm | 15-28*200 | |

Spindle | Spindle Type | type | BBT-50 |

Spindle R.P.M. | rpm | 6000 | |

Spindle Drive Type | DDS | ||

Feedrate | Rapid Traverse (X/Y/Z) | m/min | 6/10/10 |

Cutting Feedrate (X/Y/Z) | m/min | 6 | |

Tool Changer | ATC | 24 (Option: 40/60) | |

Motor | Spindle Motor | KW | 22/26 (140-286 Nm) |

Three-Axis Servo Motor | KW | 6/3/3 (38/36/36 Nm) | |

Accuracy | Accuracy | mm | 0.045/0.03/0.015 |

Repeatability | mm | 0.03/0.02/0.01 | |

Power Required | Power Requirement | kva | 60 |

Air Pressure Requirement | kg/cm² | 6^8 | |

Others | External Dimensions (L*W*H) | mm | 15600*7000*6320 |

Gross Weight | t | 77 | |

Standard Accessories

Rigid Tapping Automatic Lubricating System Semi-Enclosed Guard | Dual LED Work Light Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor | Spindle Nose Air Blow LED 3 Color Warning Light Chain Type Chip Conveyor and Cart | M30 Auto Off Leveling Bolts and Pads |

Options

Optical Linear Scale CTS 40T ATC | Tool Breakage System Chip Conveyor System Rotary Table | Oil Mist System Oil Skimmer 90° Manual Milling Head | Air Conditioner Auto Parts Probe Measuring System 90° Auto Milling Head with AHC |

About Yangsen

You should amazed by The story of Yangsen about machine tools.

Since 2003, Mr. Lin Yangbo (the founder of Yangsen) sold his first Milling machine in Fujian province when he served his former company Nuoxin as a provincial distributor. After more than 3 years of hard working and professional service, he has won the recognition of most customers in the Fujian market, and the annual sales exceed 100 million Yuan.

Unfortunately, due to poor management and management changes, Nuoxin was abruptly disbanded in 2006. Affected by this blow, Mr. Lin almost left the machine tool industry.

Inspired by the old customers who trust him consistently, Mr. Lin finally decided to transform from sales to factory production. He set up his first production lines in 2007 and recruited first batch workers and technicians. Most of them become the backbone of the company. And the story of Yangsen started from here.

With gratitude to customers and enthusiasm for machine tool, Yangsen born from a vision to provide affordable and high-quality CNC equipment to those who ever supported and trust him and who entering and experienced in the world of CNC, since 2007.

Through the deep digging of customer needs and continuous exploration of cutting-edge technology, from a small factory, Yangsen become more and professional in the design and manufacture of state-of-the-art CNC machines, enjoyed by those with a passion for CNC.

Perfect for worshop and industry use, you can find Yangsen products across the globe and in the hands of people creating inspiring and durable work.

Our Product Range:

- CNC high-speed drilling and tapping center,

- Vertical machining center,

- Horizontal machining center,

- CNC gantry machining center,

- CNC horizontal boring machining center,

- Five-axis milling machining center, etc.

YANGSEN takes science and technology as the driving force and insists on product quality. Our machine tool parts adopt well-known brand accessories, advocate high standard lean production, creating quality reputation.

- More than 20 years' experience

- Over 57,000 square meters factory and over 500 employees

- Over 5000 sets annual production capacity

- Strict quality control system

- Professional production manage system ISO9001

- On-time delivery

- Excellent quality and reasonable price

- Strict confidentiality for clients

- Complete after-sales service

- Exporting to 20+ countries

Prev: Automatic Advanced Technology Gantry Type 5

Next: CNC 5 Axis Milling Machine Gantry Type CNC Machining Center

Our Contact