Bj

Overview Package Size 1201.00cm * 233.00cm * 215.00cm Package Gross Weight 18300.000kg BJ-H630 CNC Horizontal Machining

Description

Basic Info.

| Model NO. | BJ-H630 |

| Process Usage | Metal-Cutting CNC Machine Tools, Metal-Forming CNC Machine Tools |

| Movement Method | Linear Control |

| Control Method | Closed-Loop Control |

| Numerical Control | CNC/MNC |

| Processing Precision | 0.01~0.02(mm) |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001, ISO 14000 |

| Condition | New |

| Gross Weight | 14500kg |

| Transport Package | Wooden/Iron Bracket/Wooden Box |

| Specification | 4225*2690*2485mm |

| Trademark | Josen |

| Origin | Changzhou, Jiangsu, China |

| HS Code | 8457101000 |

| Production Capacity | 3000set/Year |

Packaging & Delivery

Package Size 1201.00cm * 233.00cm * 215.00cm Package Gross Weight 18300.000kgProduct Description

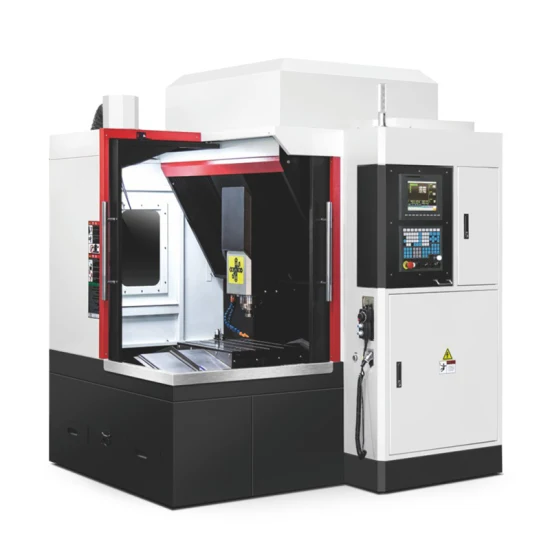

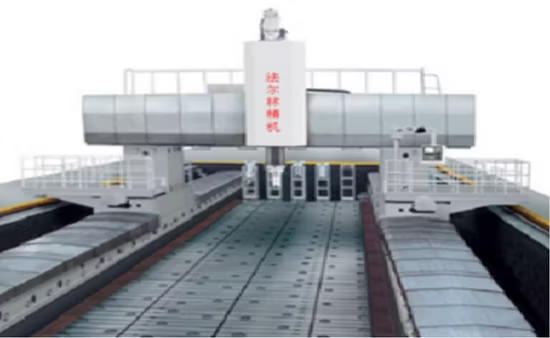

BJ-H630 CNC Horizontal Machining Center High Precision Horizontal CNC Machining Center Automatic Horizontal Machine

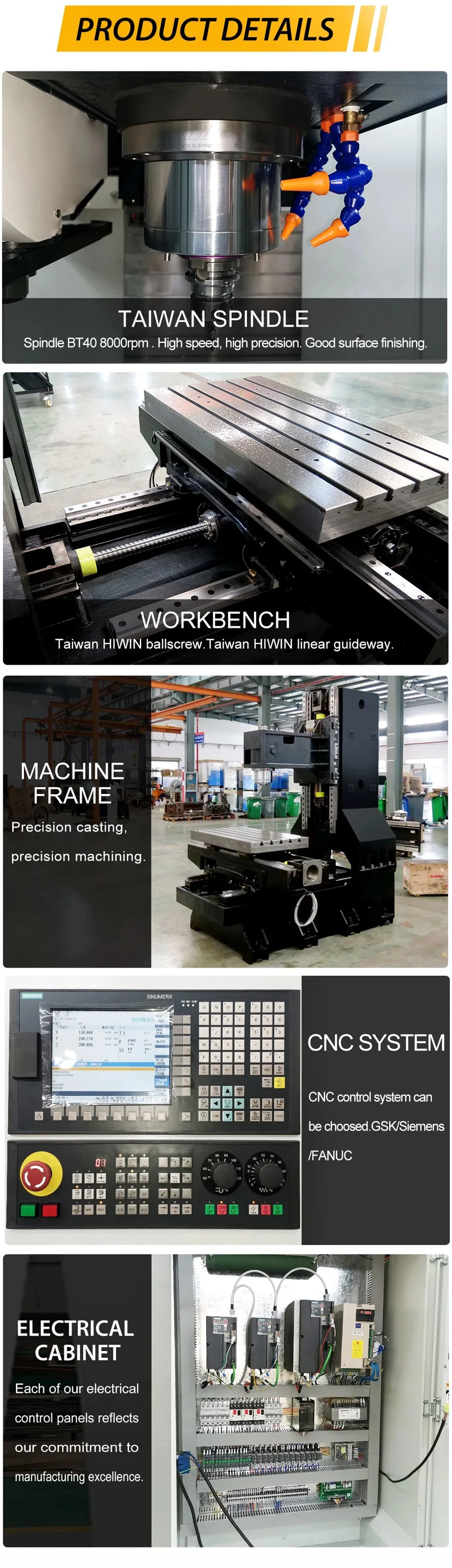

Product Specification Can be loaded into standard containers and will save at least $2000 in shipping costs.| Description / Machine Model | Unit | BJ-H630 |

| Travel | ||

| X-axis travel | mm | 1050 |

| Y-axis travel | mm | 750 |

| Z-axis travel | mm | 900 |

| Spindle center to table surface | mm | 0-750 |

| Spindle end to table surface | mm | 130-1030 |

| Working table | ||

| Working table size (X*Y) | mm | 630*700 |

| Num of working table | 2 | |

| Scale division | 1°*360 | |

| Transmission ratio | 240 | |

| Transmission ratio of exchange table | 240 | |

| Workpiece swing dia | 950 | |

| Exchange time | S | 20 |

| Working table type | M16 | |

| Max. loading capacity of working table | kg | 1000 |

| Spindle | ||

| Spindle motor | β 12/12000 | |

| Spindle speed | rpm | 12,000 |

| Spindle inner taper bore | HSK/A63 | |

| Drive Power of each axis | ||

| X drive motor | β 40/2000 | |

| Y drive motor | β 40/2000 | |

| Z drive motor | β 40B/2000 | |

| B drive motor | β 12/3000 | |

| Feed rate | ||

| Rapid feed rate (X/Y/Z) | mm/min | 24,000 |

| Fastest cutting feed rate | mm/min | 5-8,000 |

| Machine accuracy | ||

| Three-axis laser positioning accuracy (JIS6338 actual measurement method) | ||

| Positioning accuracy (full stroke) | mm | ±0.01 |

| Repeat positioning accuracy (full stroke) | mm | ±0.006 |

| Other | ||

| Floor space (L*W) | mm | 4225*2690 |

| Machine height (maximum) | mm | 2485 |

| Machine weight | T | 14 |

| Left elevation | Right elevation |

Machine Center Application: This VMC is suitable for mechanical processing and mold making .And it can adapt to the processing requirement from rough machining to finish machining .It can also finish many working procedures like milling ,drilling ,tapping ,boring ,etc.

Detailed Photos

A:We provide one year warranty, if any parts broken, we will send you a new one for free. 7.Before sending me an inquiry on our machine, it is better for you to provide me the following information?1)Your metal workpiece size. Because in our factory, we have different models according to working area.2)Your workpiece materials.Aluminum/Steel/Iron/Titanium Alloy?3) You also can send us the drawing of your workpiece, so that we can have a moe careful check and give your more accurate suggestions.

Prev: 5 Axis Machinery Vmc850 3 Axis China Fanuc Metal CNC Milling Machine Vertical Machining Center

Next: Fanuc Control Vertical CNC Drilling Tapping Milling Machine Center for Metal Vmc Cx

Our Contact

Send now